Let’s talk about an important topic that deserves some explanation: tub grinder operation. Your machine may not change, but how you operate your machine can. Here are five operating tips and features to consider.

1. Know how full the tub is

To help prevent thrown objects and run your tub grinder without spillage, make sure you’re maintaining a proper tub fill. The bowl should be filled to proper capacity (found in your operator’s manual) to help reduce the risk of the grinder throwing material.

Another helpful method is layering the material that you put into the bowl. “Try alternating layers of small material and large material every other bucket,” suggested Vermeer product specialist, Corey Harthoorn. “Grinding both small and large material together in a blend helps makes it so there’s less open air or open space in the bowl for objects to be thrown.”

2. Understanding the thrown object restraint system (TORS)

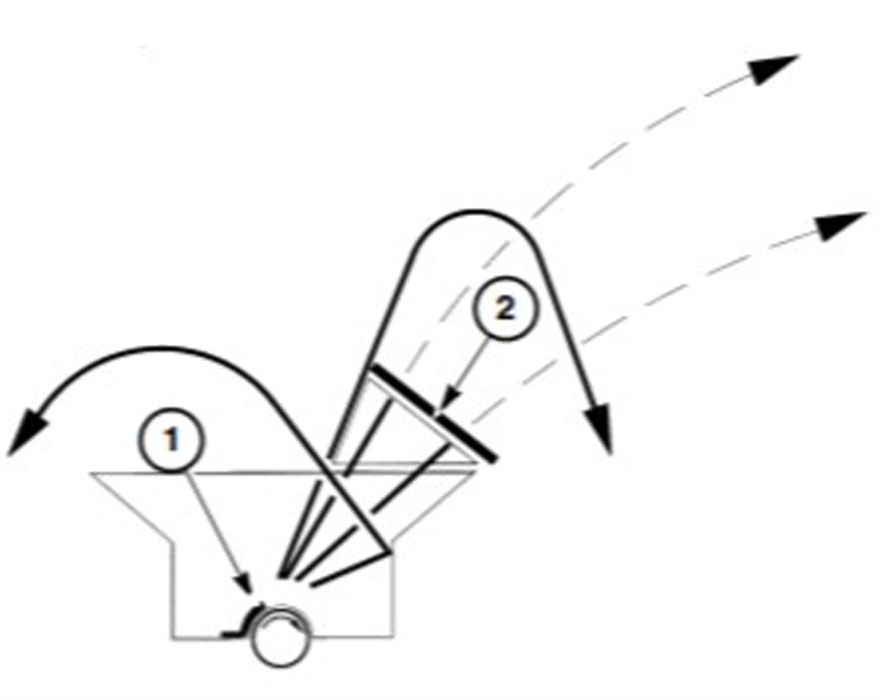

The thrown object restraint system (TORS) helps reduce the potential for throwing objects from the tub during machine operation. This system consists of a rotor deflector (1) and a tub cover (2) that work together to limit the quantity and distance of thrown objects.

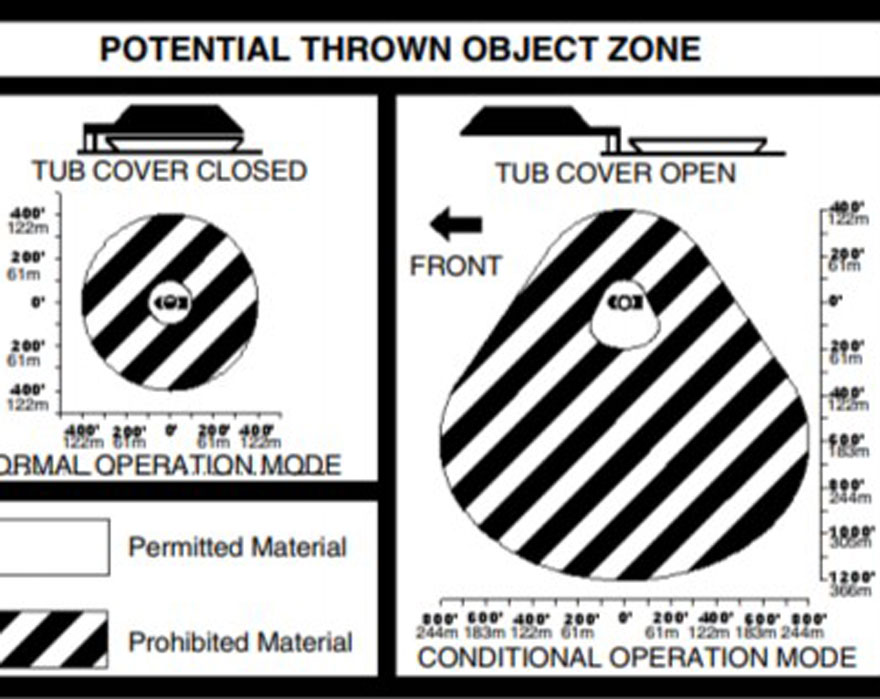

The rotor deflector and tub cover will not contain all thrown objects, but together, they limit the thrown distance of objects to the potential thrown object zone (below) for normal operation mode. Using the rotor deflector alone substantially increases the potential for thrown objects beyond the specified zone. The potential thrown object zone for conditional operations mode (tub cover open) would then apply.

The rotor deflector covers a portion of the mill/drum rotor to help prevent the hammers from striking objects in this area and throwing them from the tub. With the rotor deflector in place, objects struck by the hammers in the uncovered area of the mill/drum rotor will likely be thrown in a direction blocked by the tub cover. The tub cover helps prevent the heavier objects from being thrown from the tub.

For example, permitted material, such as paper, green waste, pallets, brush, limbs, logs, stumps and heavy wood can be thrown up to 200 ft (61 m) if the tub cover is open, and up to 100 ft (30.5 m) if the tub cover is closed. Prohibited material, which includes steel, rigid plastic, stone/masonry, glass, tires and flammable material can be thrown up to 1,200 ft (366 m) if the tub cover is open, and up to 400 ft (121.9 m) if the tub cover is closed.

With all of that in mind, it’s important to set up your work area appropriately to help protect you, your workers and other people in the area.

3. Falling object canopy

Vermeer tub grinders are also equipped with a falling object canopy over the operator ground station control panel. It is manually raised to help protect the operator standing at the ground station controls from any falling or thrown objects. Make sure that the falling object canopy is raised before operating the machine.

4. Use an enclosed cab

Another way to help protect yourself, or whoever is operating the tub grinder, is to use a loader with an enclosed cab when you’re working around the machine.

One way to do this is with the optional loader provided by Vermeer on the TG5000 and TG7000 tub grinders. The loader option also comes with an enclosed cab and a grapple.

“The loader has two main purposes,” explained Harthoorn. “First, it allows you to stay efficient by feeding the machine and filling the tub quickly. Second, it can give you an ideal view into the tub, so you can see how much material is in there and see when something gets stuck.”

5. Use these additional tips

Here are four additional tips for operating a Vermeer tub grinder.

Know how to access the hammermill

When you need to access the hammermill, there are a few things you should know. The tub opens up 91 degrees. When it opens, it disengages the tub interlock switch. The tub has to be closed to engage the mill or the clutch, it can’t operate while it’s open, to help protect you or anyone else that is working on the hammermill. Remember to follow all shutdown procedures in your operator’s manual before working on or around the hammermill area.

Stay away from the tub during operation

When the machine is running, stay out of the potential thrown object zone. The safety sign on the machine shows you the permitted and prohibited zone areas. Don’t attempt to manually dislodge materials inside the tub without following proper shutdown procedures provided in your operator’s manual.

Use the tub table safety prop

If for some reason you aren’t able to fully raise the tub, or you don’t want to dump everything in the tub, you can use the tub table safety prop to support the tub.

“There’s a mechanical lock in the tub table safety prop that will keep the tub supported,” explained Harthoorn.

All of these features are designed to help keep your crew working efficiently. Remember these five tips and make sure you’re implementing them whenever you use your tub grinder next.

Watch the operations and safety video

For additional operation and safety information, watch the Vermeer tub grinder operations and safety video. For more information about Vermeer tub grinders, contact your local dealer.

Always refer to the product’s operator’s and/or maintenance manual for safety messages and further instructions. Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2021 Vermeer Corporation. All Rights Reserved.