In 1988, Jeff Hansen began trimming trees a few Saturdays per month as a side job. Word spread and demand quickly grew. As a result, Hansen established a full-time residential tree care business in the 1990s.

The capabilities of Hansen’s Tree Service quickly evolved as the tree care business grew. In 2005, Hansen’s became the first tree care company in Missouri to be certified by the Tree Care Industry Association. The company now employs 10 arborists certified by the International Society of Arboriculture.

Vermeer as a partner

What began as a one-man side job has evolved into a business that employs 90 people and operates a fleet of 75 trucks. Diversifying the equipment fleet allowed the company to expand its offerings to enhance tree care business growth.

Despite running its equipment day in and day out, equipment is rarely traded. The company prefers to invest in quality machines and purchase additional units that add to the company’s ever-expanding list of services. Vermeer complements this business approach.

“We run machines 10, 12 or 14 years,” said Ken Byrne, vice president, Hansen’s Tree Service. “We’ve been growing since I have been here. Replacing machines isn’t as important as adding them. I am a big believer in you get what you invest in.”

As Hansen’s Tree Service grew, the team explored new services and revenue streams. Now the company performs commercial tree care, residential tree care, tree removal, stump removal, green waste recycling, land clearing for development and contract grinding. The company’s Vermeer equipment fleet includes mini skid steers, brush chippers, stump cutters and horizontal grinders. This diverse fleet allows Hansen’s Tree Service to perform more types of work.

“We started out with one Vermeer chipper, and through the years we have added many different types of Vermeer equipment. Now we own several dozen pieces of Vermeer equipment,” said Chad Hansen, president of Hansen’s Tree Service.

More business opportunities

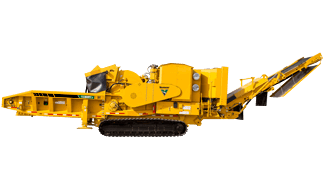

Contract grinding with the Vermeer HG6800TX horizontal grinder allowed Hansen’s Tree Service to pursue more business opportunities. With this machine in the fleet, the company has been able to venture off its own sites to perform contract grinding for other land clearing and construction companies.

The HG6800TX allows ease of transport and jobsite access due to its narrow width and a dolly system, including a 10 ft (3 m) maximum width transport with dolly. Once on the jobsite, the horizontal grinder is well-suited to the demands of large contract grinding operations. Low sidewalls aid in feeding whole trees and other large materials with less restriction. The feed roller can climb up to 50 in (127 cm), helping the machine to crush logs or stumps that need to be rolled, allowing the operator flexibility for different material inputs.

“The HG6800TX is highly productive and fairly fuel efficient as compared to some of the other machines on the market,” said Hansen. “In the clearing and construction world, customers expect you to perform. The HG6800 has been averaging 500 yd3/hr to 600 yd3/hr (382 m3/hr to 456 m3/hr) on the primary grind. This includes large logs and brush.”

Product specialist provides an advantage

The company has tried many competitors’ equipment, but it keeps coming back to Vermeer due to the service and parts availability. Recycling and Forestry Specialist Travis Ostreko with Vermeer Midwest is part of that, helping ensure Hansen’s Tree Service receives prompt service.

“Being able to call a single person who is the expert on that particular machine is fantastic,” said Hansen. “You can just call their cell and they answer. That’s not very common with competitive manufacturers. Every minute matters. Being able to get a quick answer keeps us going.”

Hansen’s Tree Service can do more with the HG6800TX horizontal grinder due to the service and support it receives from Vermeer.

“Vermeer has been able to keep us going when others couldn’t. Their machines perform and it keeps us coming back,” said Hansen.

This article contains third-party observations, advice or experiences that do not necessarily reflect the opinions of Vermeer Corporation, its affiliates or its dealers. Testimonials and/or endorsements by customers in specific circumstances may not be representative of normal circumstances experienced by all customers.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2023 Vermeer Corporation. All Rights Reserved.