Vermeer grinders promote jobsite safety in wood waste processing and construction and demolition with innovative safety features and advanced technology.

As we recognize National Safety Month, let’s explore how Vermeer tub grinders and horizontal grinders contribute to jobsite safety and the various benefits they offer.

When is National Safety Month?

National Safety Month is observed every June, bringing extra attention to safety issues across various industries. This month-long initiative, led by the National Safety Council, focuses on promoting jobsite safety and reducing risk.

For operators using tub grinders and horizontal grinders in construction and demolition and wood waste processing, National Safety Month is a crucial reminder of the importance of jobsite safety. These operators face unique challenges, some of which include the risk of thrown debris and machine damage. Vermeer grinders, equipped with advanced safety features — Thrown Object Deflector system, Thrown Object Restraint System and Vermeer Damage Defense system — help mitigate these risks. By prioritizing safety, operators can help maintain productivity while protecting themselves and coworkers from potential hazards.

How do Vermeer grinders promote jobsite safety?

Here’s a list of the safety benefits of using a Vermeer grinder for wood waste and construction and demolition contractors.

1. Thrown Object Deflector system reduces potential thrown hazards

The TOD system helps minimize the amount and distance of debris thrown during operation, enhancing jobsite safety. By deflecting thrown objects, it protects operators and nearby workers from potential injuries. This is particularly important in wood waste and mulch manufacturing environments where debris can be hazardous.

2. Thrown Object Restraint System improves operational safety

The Thrown Object Restraint System (TORS) on Vermeer tub grinders is designed to help reduce the risk of debris being ejected during machine operation. By containing and controlling the trajectory of thrown objects, TORS enhances the safety of both operators and nearby workers. This system is crucial in environments such as wood waste and mulch manufacturing, where the presence of hazardous debris is common.

3. Vermeer Damage Defense system helps prevent major machine damage

This system detects metal contaminants mixed with incoming materials. If metal is detected, it alerts the grinder control and initiates shutdown, preventing significant damage to the grinder and reducing downtime. This feature is crucial for maintaining productivity in wood waste processing and mulch manufacturing.

4. Wireless remote control enhances operator safety

Operators control the machine from up to 300 feet (91.4 m) away, allowing safer operation and better visibility of the jobsite. This remote control reduces the need for operators to be near the machine, minimizing exposure to potential hazards. This is especially beneficial in environments where wood waste and mulch manufacturing are taking place.

5. Falling object canopy protects operators from falling debris

Tub grinders are equipped with a canopy over the operator ground station control panel. This canopy is manually raised to protect the operator from falling or thrown objects, ensuring safer operation. This feature is essential in wood waste and mulch manufacturing sites where debris can pose a risk.

6. Duplex drum cutting system optimizes cutting performance

This duplex drum system enhances cutting efficiency and simplifies maintenance, contributing to safe and productive operations. The independently secured wedge system and enhanced drum balancing improve durability and serviceability. This is vital for maintaining high productivity in wood waste processing and mulch manufacturing.

7. High ground clearance and sealed rollers reduce material build-up

These features keep material from accumulating in the track system, helping provide smoother and safer operation. High ground clearance allows the grinder to traverse difficult terrains, while sealed rollers protect the feed roller planetary from debris. This is important for maintaining efficiency in wood waste and mulch manufacturing environments.

8. Proper tub fill and layering prevent thrown objects

Maintaining a proper tub fill and alternating layers of small and large material reduces the risk of the grinder throwing material. This method ensures the bowl is filled to proper capacity, minimizing open air or space for objects to be thrown. This is crucial for safety in wood waste and mulch manufacturing sites.

Vermeer tub grinders: Products available

Vermeer offers tub grinders designed to handle high-volume wood recycling, mulch operations and organic material processing.

- TG5000 tub grinder: Ideal for processing organic material, the TG5000 offers proven cutting performance with its 540-hp (403-kW) engine, proven durability and straight-forward serviceability. It features the TORS and an optional grapple loader for added versatility.

- TG5000E tub grinder: Designed for processing organic material with an emphasis on efficiency and environmental sustainability. Powered by a 500-hp (373-kW) electric motor, the TG5000E offers robust cutting performance and straightforward serviceability. It features the TORS to enhance jobsite safety and an optional grapple loader for added versatility.

- TG7000 tub grinder: Built for high-volume wood recycling and mulch operations, the TG7000 is packed with innovation and power with its 950-hp (708-kW) engine. It features the TORS and an optional grapple loader for added versatility.

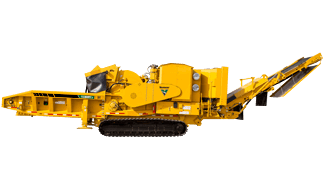

Vermeer horizontal grinders: Products available

Vermeer provides a variety of horizontal grinders built tough to suit large land clearing, municipal waste and composting operations.

- HG4000 horizontal grinder: Efficiently processes logs and other organic materials into valuable end products. It features a 536-hp (400-kW) engine and that includes an EcoIdle(™) engine control system to help with fuel efficiency.

- HG4000E horizontal grinder: Designed for stationary jobs, the HG4000E is powered by a 500-hp (373-kW) electric motor for the mill and a 50-hp (37.3-kW) motor for the hydraulic pump.

- HG6000 horizontal grinder: Versatile and tough, the HG6000 features the Vermeer intelligent feed system that allows you to spend more time feeding and less time adjusting settings. It is designed to help meet end product goals with a 755-hp (563-kW) engine.

- HG6000TX horizontal grinder: The HG6000TX horizontal grinder, powered by a 755-hp (563-kW) engine, offers robust performance for large land-clearing projects. As a tracked machine, it provides superior mobility on rugged terrains, making it ideal for challenging jobsite conditions. Equipped with the Vermeer intelligent feed system, operators can focus more on feeding and less on adjustments, while its low sidewalls facilitate easy feeding of whole trees.

- HG6000E horizontal grinder: Powered by two electric motors providing a combined 700 hp (522 kW) to the mill, the HG6000E is ideal for stationary operations.

- HG6800TX horizontal grinder: This powerhouse is built to maximize productivity and efficiency. It features a 950-hp (708-kW) engine on a tracked machine with a compact design to power through tough material.

How Vermeer dealer specialists improve jobsite safety and productivity

A Vermeer recycling and forestry specialist supports customers by working to help ensure safe and efficient operation of their equipment.

These dealer specialists offer guidance on machine setup, operator training and preventive maintenance, which helps minimize risks and enhance jobsite safety. Their industry knowledge allows them to optimize equipment performance, ensuring customers get the most out of their Vermeer tub grinders and horizontal grinders. They assist in building the ultimate fleet tailored to specific operational needs, whether it’s for wood waste processing or construction and demolition projects.

By being available to address any issues, Vermeer specialists help maintain productivity and reduce downtime, making them an essential part of the customer’s team.

To learn more about Vermeer grinders, contact your local Vermeer dealer.

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo and EcoIdle are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2025 Vermeer Corporation. All Rights Reserved.