Did you know that all Vermeer brush chippers have a feature called SmartFeed? SmartFeed is a patented feed-sensing control system that monitors engine rpm and automatically stops or reverses feed rollers when necessary. SmartFeed also senses feed roller jams and responds by automatically shifting material back and forth, reducing the need for manual control bar manipulation.

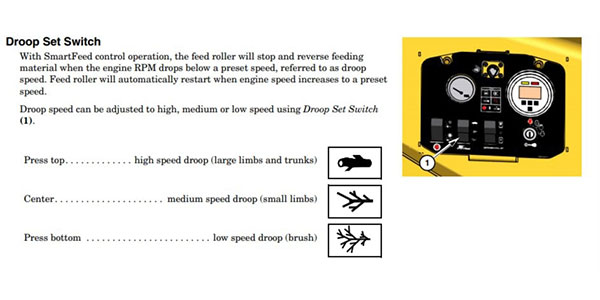

This exclusive system from Vermeer helps improve operator productivity and helps reduce strain on vital engine parts, as rpm settings are adjustable and automatically monitored. With a switch, operators can choose between three rpm droop settings to fit the job’s specific application. These three rpm settings offer versatility for varying applications. Let’s go through the settings and explain each one.

High speed droop

First, there’s the high speed droop setting. This is recommended to use when you’re feeding large limbs and trunks through the machine. Without a speed droop, loading large limbs can cause the engine to slow down and then increase beyond the original speed setting, eventually causing the engine to shut off due to overspeed. So, the speed droop helps the engine rpm speed slow down without losing its power.

When this happens, the engine may not sound like it’s working as hard, but it’s still keeping a high amount of power to shred large limbs. The SmartFeed feed-sensing control maximizes productivity by stopping and reversing the feed roller to optimally process large, hardwood material.

Medium speed droop

The center button, the medium speed droop, should be used when feeding small limbs or branches into the brush chipper. When this happens, the drum may be slowing down, but it’s doing so to optimize the productivity and efficiency of the brush chipper.

Low speed droop

When you’re loading mostly brush into the chipper, the low speed droop (the bottom setting) is recommended. Since you aren’t feeding in large branches, the machine doesn’t have to work quite as hard, allowing the machine to droop to a lower speed, while still maintaining efficiency.

The SmartFeed settings are just one way that Vermeer uses technology to maximize productivity. As you use your Vermeer brush chipper, make sure that you’re using the recommended settings as you feed the machine.

If you’re in the market for a new brush chipper or have questions about which size of machine will be best for your operation, start by learning more about the latest Vermeer models by visiting vermeer.com. If you’re ready to make a decision, contact your nearest dealer.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2021 Vermeer Corporation. All Rights Reserved.