If you’ve been around brush chippers long enough, you’ve probably heard talk about drums, discs, two knives and four knives. But what do those terms mean? Is disc better than drum? Are four knives better than two knives? We’re going to break it down below to help you understand the difference between drums and discs and two knives and four knives, as well as which type might be best for your operation.

Drum vs. disc

First, let’s discuss drums and discs. The two primary brush chipping industry methods use a drum- or disc-style chipper. The debate between the two typically depends on who you talk to, as both are capable of doing the job. Vermeer wood chippers offer disc-style chippers in the Vermeer BC700XL and BC900XL brush chipper models but use drums for the rest of the lineup (BC1000XL to BC2100XL brush chippers). Below are some differences between the two types.

On drums, the knives are mounted on the drum and cut in somewhat of a scooping motion. The drum is horizontally oriented. Drum chippers typically have little space behind the feed rollers, minimizing the opportunity for material to get lodged or jammed behind it.

On discs, the knives are mounted to the face of a disc, which cut across the grain of incoming material at roughly a 90° angle. The size of the disc is determined by the material size to be chipped (i.e., chippers with less material capacity will use a smaller disc; while higher capacity machines will use a larger disc). Disc-style chippers tend to be used in smaller brush chippers, since the disc can be smaller, lighter weight and use smaller engine configurations.

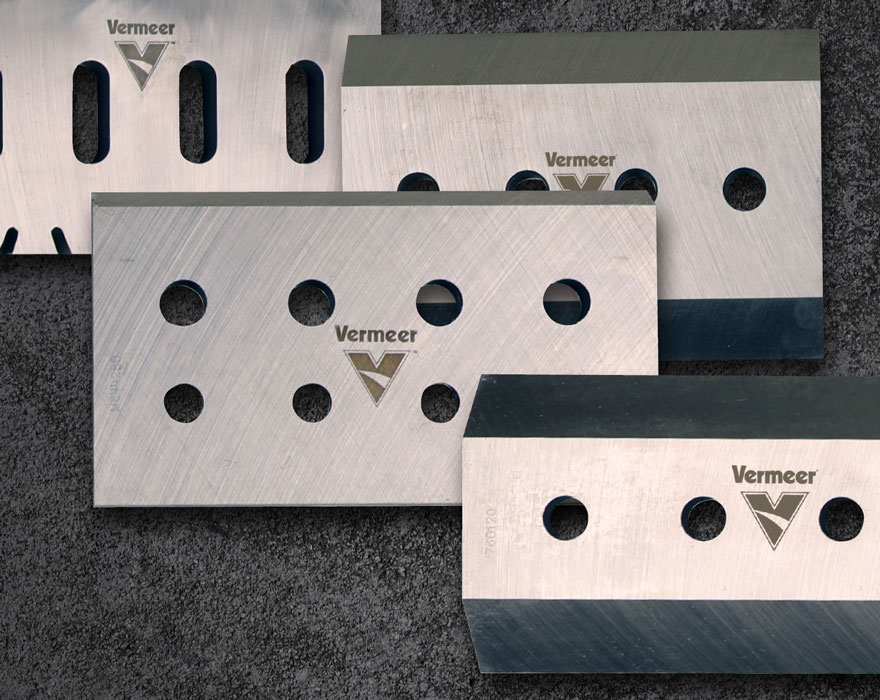

Dual-edge knives

Regardless of whether you use a drum- or a disc-style chipper, it is important to maintain sharp knives. Vermeer brush chippers use dual-edge knives which allow you to flip the knife for a second use. This design maximizes the wear life of the knife so users can replace knives less often than single-edged knives. Vermeer knives are also able to be sharpened and reused again.

Overall, sharp knives help you chip a consistent size and can minimize material jams. If your knives become dull, they can impact the efficiency of your wood chipper.

Two-knife drum vs. four-knife drum

Now, let’s talk about the difference between two knives and four knives.

“Generally, smaller chippers have two knives and larger chippers have four knives,” explained Cole Chesnut, Vermeer applications specialist. “For instance, the Vermeer BC1000XL gas brush chipper has two knives and the Vermeer BC1800XL gas brush chipper has four knives.”

This has to do with the diameter of the brush chipper’s drum. Spinning a large diameter drum at the same rate (rpm) of a small diameter drum with the same number of knives would achieve a similar feed rate and chip size, but spinning a larger drum at that rate would mean a much higher knife tip speed and higher spinning forces acting on the drum. Increasing from two knives to four knives for the bigger drums increases the number of cuts per revolution and allows operators to reduce the rpm to help make everything run smoothly.

“If you take the BC1800XL brush chipper again, for example, it has a 36-inch (91.44 cm) diameter drum,” said Chesnut. “When you have that big of a drum and four knives, it doesn’t have to spin as fast to be effective.”

Whether you have a two-knife drum or a four-knife drum on your wood chipper, you want to make sure you’re chipping at an effective rate to maximize productivity. “The market-accepted speed is 100 feet (30 m) per minute of material being fed into the chipper,” said Chesnut. “So, you want to be as close as possible to that number in terms of the speed the material is moving.”

The good news is that this can be accomplished no matter how many knives you have. “You can get to that speed with either two knives or four, but a larger diameter drum can achieve this with more knives while spinning at a lower rpm, while smaller drums with two knives need to spin at a higher rpm,” said Chesnut.

For more information about brush chippers, knives and drums, contact your local dealer.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2021 Vermeer Corporation. All Rights Reserved.