If you could update your stump cutter wheel and cutting system, would you? If it would lead you to maximize your productivity, would that help make your decision? Recently, Vermeer developed the Vermeer cutting system (VCS). This patented design specifically solves several challenges associated with traditional cutting systems. Read on to learn more about this new system and how it could enhance your stump cutting jobs.

New tooth and bolt design

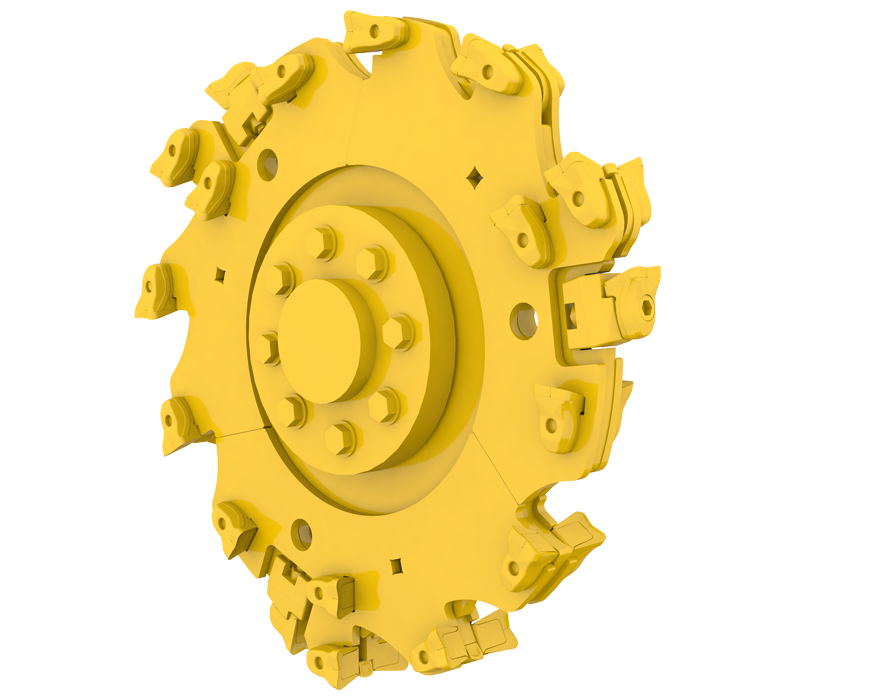

One of the main areas of enhancement is around the tooth and bolt areas. The VCS tooth design is convenient to use and maintain. It features an updated mount and retention structure.

The VCS design also utilizes a single bolt for all VCS teeth and only two tooth part numbers. Each tooth bolt has ease of access with either a torque wrench or impact wrench. No special tools or disassembly needed for access to these bolts to help with ease of maintenance and daily upkeep.

According to Josh Vrieze, senior product manager for Tree Care, Rental and Landscape at Vermeer, the VCS solves many of the challenges associated with traditional stump cutting systems. “Torquing cutter teeth daily is pretty common for most stump cutter users,” he explained. “Bolts that aren’t torqued properly tend to rotate in the pocket, causing premature wear and impacting the performance of the cutter wheel. The tooth design on the VCS has a mounting and retention structure that helps keep teeth from shifting while absorbing the shearing force, instead of the bolt securing the tooth to the cutter wheel while operating. This design makes it possible to secure each set of teeth with a single long bolt and reduces the need for retorquing.”

New profile

Similar to the Yellow Jacket™ cutter system, the VCS features two cutting edges, providing the operator maximized cutting performance. Additionally, the design of the cutting system helps protect the bolt from the shear force of the cutting action.

The V-profile of the carbide optimizes cutting productivity and the industrial carbide material gains productivity at the stump.

Even though the VCS retains the two-sided cutter design, it’s unique because rather than rotate in the pocket, the tooth is flipped to the other side of the wheel to access the other cutting edge. At the machine center’s core, there are inserts between the teeth on each side to help keep them protected.

New wear plates

Another enhanced feature is the wear plates on the VCS. Made from AR500 high-abrasion steel, the wear plates are designed for longevity. Another perk is they can be replaced as needed at a fraction of the cost of replacing the entire wheel.

Overall, the wheel design and placement of the teeth allow for material to flow past the wheel after being cut, helping reduce the recirculation of material and maximize efficiency.

With the VCS and ever-popular, industry-proven Vermeer Yellow Jacket™ cutting system, contractors now have more options to choose from. The VCS is offered on larger Vermeer stump cutters and across the entire line in the future. It’s also an option to purchase for your current stump cutter if you want to replace your cutting system right away.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo and Yellow Jacket are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2022 Vermeer Corporation. All Rights Reserved.