Brush chippers and stump cutters have been engineered to allow tree care workers to tackle difficult jobs efficiently. These products are designed to cut wood precisely, with wearable knives and teeth that need to be replaced periodically through routine maintenance. Dull knives and teeth require more power, accelerate machine wear and produce a less consistent product.

Wearable parts on brush chippers and stump grinders extend beyond the cutting knives and teeth. Other common wearable components include belts, bearings and fastening hardware. With use, these consumable components need to be replaced. Consider fastening hardware used on knives. These fasteners are subjected to forces that induce metal fatigue. While they might appear to be in good working condition, they should be replaced at specified intervals. Refer to your machine’s operator’s and maintenance manual for safety messages and further instructions.

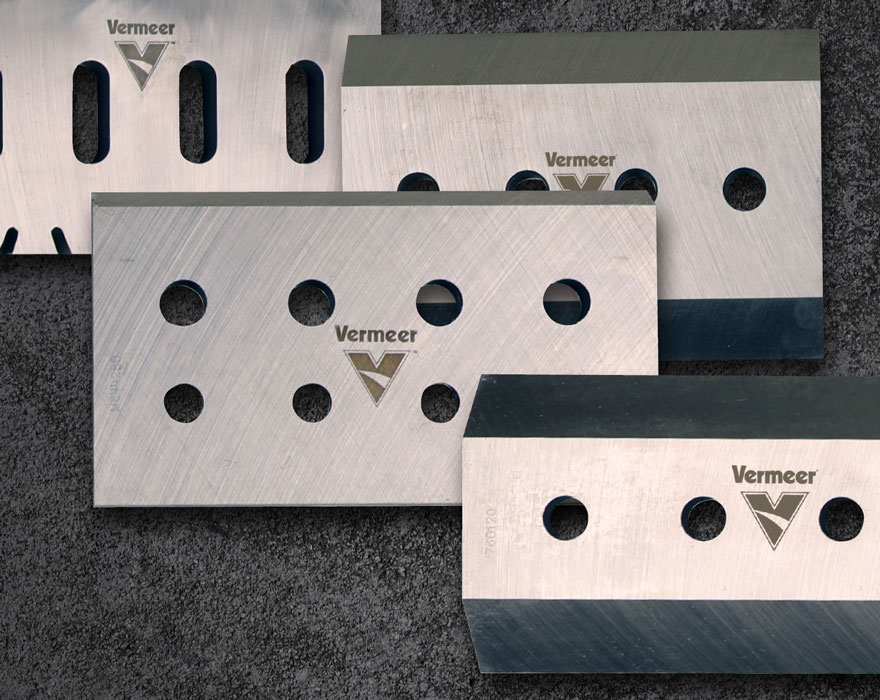

Maintain sharp brush chipper knives

The knife is the hardest working component of a brush chipper. “Knife maintenance is the No. 1 priority for rental companies or customers,” Vermeer Tree and Landscape Product Specialist Kyle Newendorp said. A sharp knife allows for a clean cut and produces a smaller chip that can be thrown farther. “If your knife is getting dull, it’s like taking a hammer and hitting that piece of wood. That’s very strenuous on all the engine parts and the bearings on the drum of the machine.”

Typically, knives should be checked at 10-hour intervals. Refer to the operator’s manual for your specific machine. Knife maintenance intervals are heavily influenced by the type of wood being chipped and the chipping conditions.

Knives can be flipped, or they can be sharpened at your local Vermeer dealer. But they need to be inspected first. Thoroughly clean the knives and inspect both sides for cracks or distortions. If any are found, discard the knives and install new ones.

Fasteners that hold the knives in place are consumable items. “You can flip the knives once with the same bolts. Then the bolts need to be replaced due to metal fatigue,” Newendorp said. Before reusing these bolts, inspect the treads for damage, corrosion or distortion. Make sure the bolts are torqued to the correct spec.

The distance between the bedknife and the knife must be checked any time work is performed on the cutter drum. “The log is sliced on the bedknife, so when you tighten the bolts or flip the knives, you need to make sure you’re testing the distance between the knife and the bedknife,” Newendorp advised. “If the distance is too far, you’re going to be shredding the log and it won’t produce a nice chip. If the distance is too close, it can cause damage with steel-on-steel contact.”

Adjust tension and inspect drive belts

Some Vermeer machines, such as stump cutters and the Vermeer BC1000XL brush chipper, are PTO-style machines that operate using belt tension. There’s no clutch to maintain, but there is a belt that deserves attention. “Make sure it’s tightened to the proper spec. This helps prevent slippage and power loss to the drum,” Newendorp explained.

“Replace the belt according to the machine’s maintenance manual. For instance, the drum drive belt on the BC1000XL should be replaced every 500 hours, or more often if it shows signs of damage or wear.”

Inspect stump grinder teeth

Vermeer stump cutters depend on cutter wheel teeth to quickly remove tree stumps and roots by cutting and grinding. Proper maintenance of the cutter wheel helps maintain productivity. You should check the cutter wheel every day or when there’s a drop in performance. Attentive operators may even note a change in the shape of the shavings, which can indicate worn or broken teeth.

Dull teeth slow down the job and may cause the machine to vibrate as it works harder. To inspect the stump grinder teeth, properly shut down the machine and rotate the cutter wheel by hand. Look for worn, broken or missing teeth. Once the tip becomes rounded, the ability to cut diminishes. Generally, the outer teeth wear faster than the inner ones. “As a general rule of thumb, if your teeth are duller than the tip of your finger, they should be flipped or traded out for new teeth,” explained Newendorp.

Vermeer stump cutter systems are designed to help extend tooth and pocket life. There are two cutting edges on each tooth. When one edge is cutting, the other is protected.

Rely on factory parts

The parts and components of Vermeer brush chippers and stump cutters have been designed to work together. Dealers have the knowledge to help ensure machines are properly maintained. “The relationship between the dealer and the customer maximizes the life of the product,” said Newendorp. Dealers can help monitor the hours on the machine and communicate with the customer on what should be replaced at 100 hours, 250 hours and 1,000 hours.”

The wearable components on the machines have been engineered to precise specifications and tolerances. Using Vermeer replacement parts takes the guesswork out of the equation.

Before purchasing aftermarket wearable parts, consider the tradeoffs. Aftermarket parts can affect the factory warranty. “If something happens to the chipper due to the outside parts you get online or through a different vendor, that part of the chipper might not be warrantied,” Newendorp explained.

To learn more about Vermeer stump cutters and brush chippers, contact your local Vermeer dealer.

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2022 Vermeer Corporation. All Rights Reserved.