In the early 1950s, Gary Vermeer was facing a formidable foe: tree stumps. Millions of them were entrenched in agricultural fields across the corn belt. Gary was grinding his teeth in search of a better way to remove them. Anything but digging them out — a highly labor-intensive process.

In 1957, a Vermeer test crew pitted a novel machine against that common adversary. The crew quickly discovered the best way to grind a tree stump is with a side-to-side cutting motion, sweeping across back and forth.

It was an innovation in tree care equipment — this approach still drives modern stump cutter technology. And the desire to find solutions still drives product development at Vermeer.

“Our testing methods are designed around solving a problem,” said Randy Runquist, manager of cutting edge research and development at Vermeer. “They are designed for a particular product.”

Once a new product is introduced, the enhancements never stop.

“Researching, refining and improving upon our high-quality products is part of the core culture at Vermeer. We are constantly looking for ways to improve every machine component to enhance our customers’ experience,” continued Runquist.

Continuous improvement drives stump cutter advancements

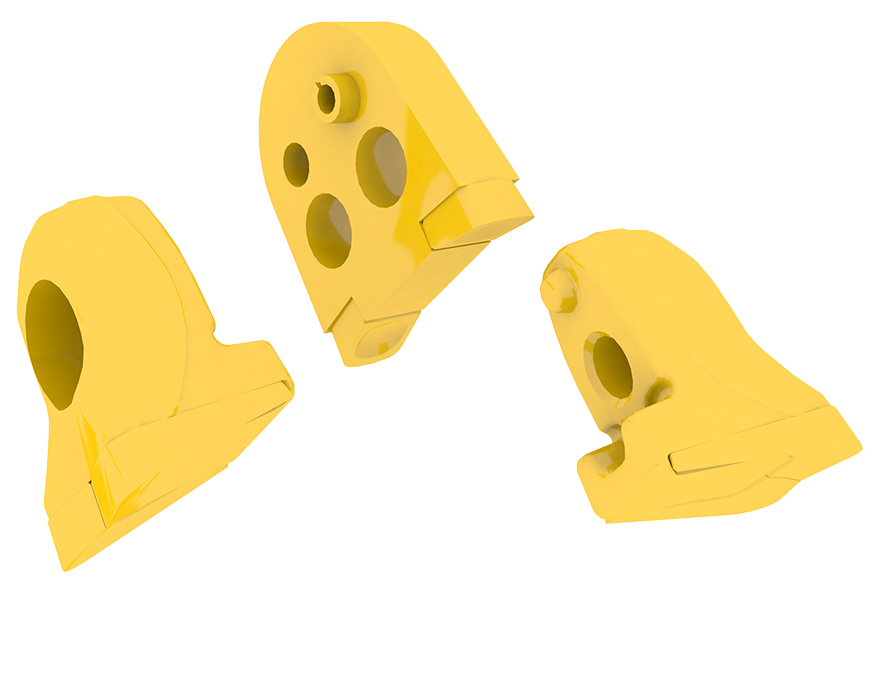

This focus on finding a better solution has led to continual advancements in the Vermeer stump cutter product line — right down to the cutter tips. Models ranging from 25 hp to 115 hp (18.6 kW to 85.8 kW) minimizes the labor-intensive work of removing even the most challenging hardwood tree stumps. An example of this continual improvement is the introduction of the Vermeer cutting system (VCS). The VCS wheel gives customers a second cutter wheel choice when deciding which wheel best compliments their business needs. One of the main challenges the research and development team wanted to solve was the tooth and bolt wear. This was an issue with many of the stump cutting systems available.

“Torquing cutter teeth daily is pretty common for most stump cutter users. Bolts that aren’t torqued properly tend to rotate in the pocket, causing premature wear and impacting the performance of the cutter wheel,” said Josh Vrieze, Vermeer senior product manager for Tree Care, Rental, Landscape. “The tooth design on the VCS has a mounting and retention structure that helps keep teeth from shifting while absorbing the shearing force, instead of the bolt securing the tooth to the cutter wheel while operating. This design makes it possible to secure each set of teeth with a single long bolt and reduces the need for retorquing.”

The VCS design is another innovation for the tree care equipment industry. It features a single bolt for all VCS teeth and only two tooth part numbers. Each tooth bolt has ease of access with either a torque wrench or impact wrench. No special tools or disassembly are needed for access to these bolts.

The VCS features two cutting edges, providing the operator maximized cutting performance. The design of the cutting system helps protect the bolt from the sheer force of the cutting action. The new V-profile of the carbide optimizes cutting productivity and the industrial carbide material gains productivity at the stump. The VCS retains the two-sided cutter design, but rather than rotate in the pocket, the tooth is flipped to the other side of the wheel to access the other cutting edge.

Focused on solutions

Vermeer continually innovates to provide tree care solutions that solve customer challenges. Products are relentlessly refined in the never-ending search to find a better way. Contact your local Vermeer dealer today to discover how they can help find solutions for your job site.

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2023 Vermeer Corporation. All Rights Reserved.