It started as a hunch. But that market instinct three decades ago re-shaped Vermeer Corporation and created lasting impacts felt from Pella, Iowa all the way to your home modem.

That business intuition? Vermeer needed to get into the horizontal directional drilling business.

A company long known for creating forage solutions, Vermeer launched its first horizontal directional drills in the early 1990s. Within a decade, HDD product sales represented half of the company’s business.

Now, Vermeer is the HDD market leader, innovating solutions for fiber, electrical, oil, gas and water installation. To commemorate the Vermeer 30-year legacy in horizontal directional drilling, company leaders gathered to recall the journey in an extensive roundtable discussion.

“I’m so proud of Vermeer and it being the market leader in HDD for almost 30 years now,” Doug Hundt, president of Industrial Solutions at Vermeer, said at the event. “That in itself is a remarkable feat, because that only happens with the right people, the right ownership, long-term thinking and continuous improvement. … The future is bright. And we’re very fortunate this product line will continue to make an impact around the world.”

Here are key excerpts, some edited for clarity, of that conversation on the Vermeer legacy in horizontal directional drilling.

Vermeer HDD legacy: A hunch hits big

Vermeer founder Gary Vermeer had previously considered the idea of adding a boring tool — something that could mimic a mole. Inspired by the animal, Vermeer wanted a tool that could bring infrastructure into the ground with minimal disruption.

When the idea of a pneumatic ground-piercing drill was pitched in the late 1980s, Vermeer supported the idea. Company leaders tasked Pat Weiler, then the head of the Specialized Products Division at Vermeer, with developing the company’s first underground boring equipment.

Find your local Vermeer dealer

Mary Andringa, Vermeer CEO 2003 – 2015:

In some board notes I read recently, in 1990 Gary’s goal was to get five units out by February of 1991 to sort of test the market, test the units. We had five units out in February 1991 with rave reviews from the dealers and the customers who started using them. First it was called “EZ Bore,” and then as I understand it, our dealer out in Oregon said, “Oh, we ought to call it ‘Navigator.’” That stuck.

Doug Hundt:

Did you see a big vision for this product line? Did you see it as just diversification? Or was it to try to fill the channel that the dealers needed?

Mary Andringa:

The major thing was dealers pushing it. My dad said, “I always thought there should be a better way to put in utilities.” He wasn’t involved in the design, but he was very interested in it. We had a few dealers who were starting to sell it — and that pushed us to think about the product lines.

In 1990, Weiler tapped Vermeer engineer Jim Rankin to lead his HDD development team.

Hundt:

How did you get involved? What did Pat come and say to engineering?

Rankin:

He pulled me in the office one day and he said, “What do you know about directional drilling?” I said, “Absolutely nothing. I don’t know what you’re talking about.” And he says, “Well, I know nothing about it either, but the family says we’re going to do it.” I said, “OK.”

Understanding the need for HDD solutions

Gary Vermeer’s hunch proved correct. But early on, it was unclear whether the Vermeer HDD investment was wise.

Hundt:

Let’s talk about the first couple of years. Now we’re in the market, you’ve got a machine, there’s a couple of competitors out there. Vermeer is in the game. What happened next?

Rankin:

A lot of manual labor, because we were carrying the rod out. We had to push the rack out. We were pounding stakes in with a sledgehammer, and it was an extreme amount of manual labor. It wasn’t a popular way to install yet. It was seen as extremely expensive. So we started digging in, trying to reduce that.

Rankin and another Vermeer engineer, Pete Rozendaal, worked on early Vermeer HDDs to identify improvements and separate the company’s boring equipment from competitors.

Rankin:

We were kind of the design team, product support team and the service team. We would go out, take a machine and bore. We would come back saying, “Oh, that was a lot of work. Let’s change this.” Then we’d sit down and try to make it more practical and easier to do.

One of the key innovations in the Vermeer HDD journey came through conversation with a customer. Gary Nirich, a strategic sales manager for Vermeer, helped relay feedback to the engineering team.

That suggestion made Vermeer HDD equipment stand out from the rest.

Rankin:

(The customer) says, “I want a small drill — curb to house — that I can sit on and just drill.” … The best information comes from the customer.

That request eventually led to the previously trailered D24x40 becoming a self-contained unit.

After Vermeer became the first to have a self-contained unit in 1993, that once-hazy market was no longer difficult to read. The company’s HDD equipment was a smashing success.

Mary Andringa:

Sales went up astronomically. We went up 400% the second year and another 100% the year after that. By the end of the ’90s it was half of our business.

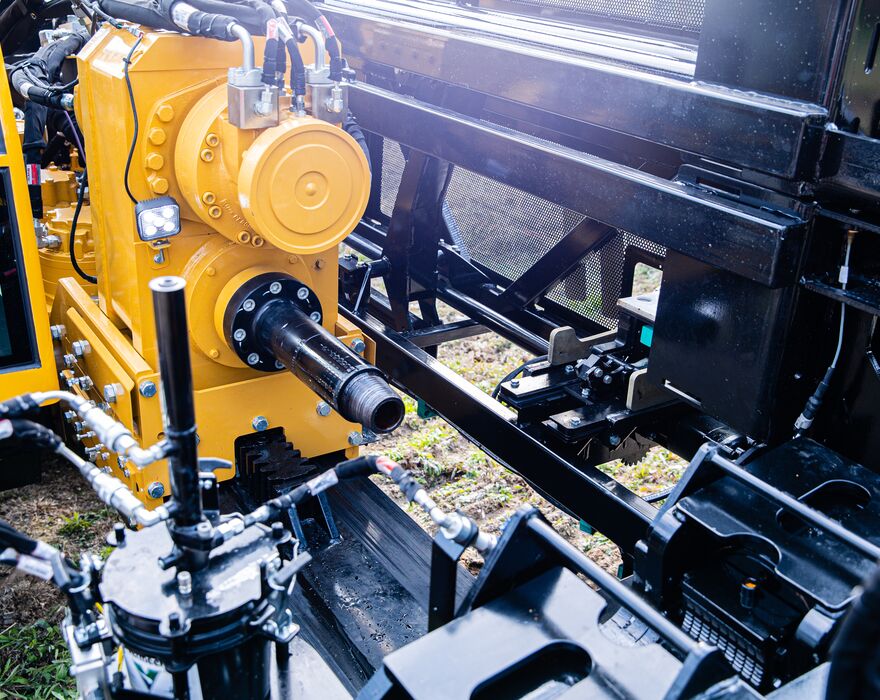

Horizontal directional drilling innovations: Evolution of Vermeer HDD machines

Over the next three decades, Vermeer engineers created numerous HDD innovations: class-leading cycle times, quieter drills ideal for dense residential areas, cutting-edge telematics — the list goes on and on.

But like the self-contained set-up, another market-leading innovation was created in the mid-1990s: The Vermeer rod loader.

Hundt:

There’s all kinds of lore around how the rod loader was invented. Tell us that story. How did that come to be?

Rankin:

All credit goes to Pete Rozendaal. He suggested, “What about a toothpick dispenser? What about a straw dispenser at a restaurant?”

Hundt:

So the idea came from fast food restaurants?

Rankin:

Basically. … And anybody that dispenses toothpicks.

Hundt:

That simple. How did you take that and make something that works?

Rankin:

Well, Pete did that. I give him credit for a lot of the things that happened. But that was how it all started. And the old 24x40A and 24×40 pretty much follows a straw feeder or a dispenser in that way.

Another improvement in that time was the introduction of the Vermeer Firestick® drill rod.

Rankin:

When you think of everything that’s happened on a drill, all the innovation, the No. 1 thing is the rod. Because we could fix everything above ground, put our hands on it, but we couldn’t fix what was going on down below.

Ed Savage, Vermeer segment manager and past HDD product specialist:

And that really led the industry, that one piece of forged rod. It really did.

Rankin:

That one piece really made it take off.

Hundt:

What about the competitive landscape? During the mid to late 90s — was Vermeer in the lead? And what did the competitive landscape look like?

Savage:

There were a lot of competitors back then. We had Earthworm, Underground Tools Inc., Barbco, American Augers. Some of them did bring some unique things to the industry too, like rack and pinion. It’s good to have some of those competitors to push you.

Hundt:

Jason, I’m curious — you obviously weren’t in the business back then since you were a young man, but what are some of your early memories of HDD and the stories you’ve heard?

Jason Andringa, current Vermeer CEO:

I remember this sense that things were improving very quickly when it came to HDD, that we knew we’d started out with something fairly rudimentary, but every year we were developing new, exciting ideas and implementing that. It’s remarkable to sit here now and think about how much we’ve continued to innovate over the last 18 years. I remember coming in 2005 and feeling like, “Hey, HDD’s come a long ways, fairly mature technology.” Not even close.

Need horizontal directional drill parts? Visit Borestore.com

The future of Vermeer horizontal directional drilling

The early 2000s brought numerous challenges. Sales for HDDs dropped by 90 percent between 2000 and 2003, and Vermeer steered through two recessions.

But those hiccups eventually gave way to explosive growth in utilities over the last 15 years, due in large part to investments in hardening infrastructure and expanding fiber internet access.

Hundt:

We’ve been in this market for about 30 years now. What direction do you think it’s headed in? What kind of innovations can we expect to see in this space?

Clint Recker, Vermeer product manager for utility HDD:

The main challenge that our customers face now is labor. There’s not enough people to be able to do the job and run the equipment. Training continues to be a part of that. And there’s different ways that we’re focusing on training than compared to the past. But it’s really designing equipment that can be as productive as possible and figuring out ways to decrease that learning curve to put an operator on a piece of equipment and get them up to par. And looking to the future to see what we can do there to reduce the amount of effort that’s required to complete a job.

Hundt:

How does digital play into that?

Recker:

As more infrastructure has gone into the ground, that makes it more challenging for the job site. It takes longer for the crew to locate all those utilities that are already in the ground. And certainly there is skill involved with that. The team was developed with the Atlas Bore Planner® computer software, all the way back in the 1990s, working to be able to put all those utilities into a digital tool so that you can find a solution to navigate around them. And our digital offerings have continued to increase in that space with regards to bore planning. We’re also looking at the productivity side of it as well. When we look at telematics, using that tool to be able to help with the productivity of our equipment — understanding where they’re at, how much work they’ve done, understand if there are any problems with the piece of equipment.

Hundt:

Do you believe that HDD has a bright future?

Recker:

Yes. Absolutely.

Hundt:

If Vermeer would’ve never gotten into HDD, where would we be today as a company?

Jason Andringa:

Vermeer is incredibly proud of being the inventor of the round baler, continuing to serve a role in the forage market. We are very proud to be the inventor of the stump cutter and play a role in tree care rental, landscape, recycling and more. But over the last 30 years, without question, HDD has become the most important line of products within Vermeer. That has been the case over the last 30 years historically. But at this point, looking forward into the future, it’s hard to think of any group of products that can displace HDD in the near or medium term.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo, Equipped to Do More, Firestick and Atlas Bore Planner are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. All other trademarks, registered trademarks and service marks are the property of their respective owners. © 2024 Vermeer Corporation. All Rights Reserved.