As communities grow across the southeastern United States, the need for new underground infrastructure keeps increasing. T B Landmark Construction, Inc. knows that getting this work done takes powerful, reliable equipment. That’s why they count on the D100x140 S3 horizontal directional drill for their pipeline and infrastructure projects.

D100x140 S3 performance on pipeline projects

“The D100x140 really hits its sweet spot when drilling 1,500 ft (457.2 m) with 16-in to 20-in (40.6-cm to 50.8-cm) product,” said BJ Bourgholtzer, operations manager at T B Landmark. “In good ground conditions, we can push it to 3,000 ft (914.4 m) with 12-in (30.5-cm) diameter pipe, but our bread and butter is really those 1,200 ft to 2,000 ft (365.8 m to 609.6 m) shots with 12-in to 20-in (30.5-cm to 50.8-cm) product.”

From their Florida headquarters, T B Landmark crews put these capabilities to work throughout the southeastern United States, including Florida, Georgia, South Carolina, North Carolina and Maryland.

Design for urban HDD projects

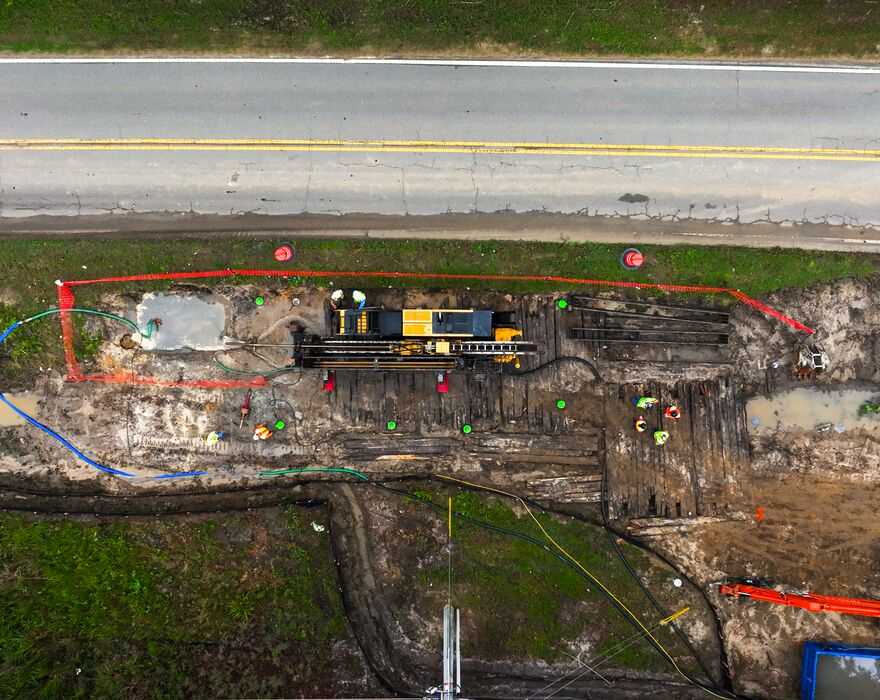

Compact yet powerful, the D100x140 S3’s design makes it ideal for urban horizontal directional drilling projects, where space is limited. “The machine’s footprint is really efficient,” said Bourgholtzer. “You’ve got baskets that hold 180 ft (54.9 m) of rod that you can double stack, giving you 360 ft (109.7 m) before needing to change baskets. Compare that to larger maxi rigs where you’re loading rods one by one and need a much bigger setup area.”

This compact size really helps in cities where space is tight. “For these infrastructure jobs, they’re not giving you a whole lot of room,” said Curt Curtis, drilling superintendent for T B Landmark. “I’m looking at a 12 ft (3.7 m) right-of-way, 300 ft to 400 ft (91.4 m to 121.9 m) from access. The D100x140 is still the one for the job.”

HDD solutions for pipeline installation

The D100x140 S3 helps T B Landmark tackle all kinds of pipeline projects. They recently finished several major installations around Jacksonville, putting in 1,200 ft to 1,500 ft (365.8 m to 457.2 m) sections of 8-in (20.3-cm) steel pipe.

Powerful performance across ground conditions

Adapting to varied soil conditions in the Southeast requires equipment that is both strong and versatile, and the D100x140 S3 delivers on both fronts. “When we show up on a jobsite with our Vermeer machines, we’re confident they’re going to perform,” said Bourgholtzer. “We’re going to outperform our competitors.”

The machine’s power lets T B Landmark adjust to different ground types while keeping projects moving forward. They can control drilling speed and mud flow to match soil conditions, which helps protect the pipe during installation.

Horizontal directional drilling for infrastructure growth

As more people move to the Southeast, cities need bigger and better utility systems. T B Landmark works with many local governments to build new lines and fix old ones that need repairs.

The D100x140 S3 has become a key part of T B Landmark’s success. With multiple machines running almost year-round, the drill’s combination of power and compact size enables them to take on increasingly challenging projects. “We’ve used it successfully across North Carolina, South Carolina, and now we’re heading to the panhandle. It adapts well to all these applications and consistently delivers results,” said Doug Tyus, fleet manager for T B Landmark.

“The D100x140 S3 is a staple for our company. We’ve had ’em for over 12 years now, and I don’t foresee that ever changing. It’s just such a versatile drill. You have to have it in your fleet,” said Bourgholtzer.

Ready to learn more about how the D100x140 S3 HDD can transform your pipeline and infrastructure operations? Contact your local Vermeer dealer today.

This article contains third-party observations, advice or experiences that do not necessarily reflect the opinions of Vermeer Corporation, its affiliates or its dealers. Testimonials and/or endorsements by contractors in specific circumstances may not be representative of normal circumstances experienced by all customers.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications. Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2025 Vermeer Corporation. All Rights Reserved.