If your HDD crews are frequently swapping drill bits out on the job — utilizing valuable working time — and you are looking for an efficient solution, the Ultra X3 drill head system could be the answer you’re looking for.

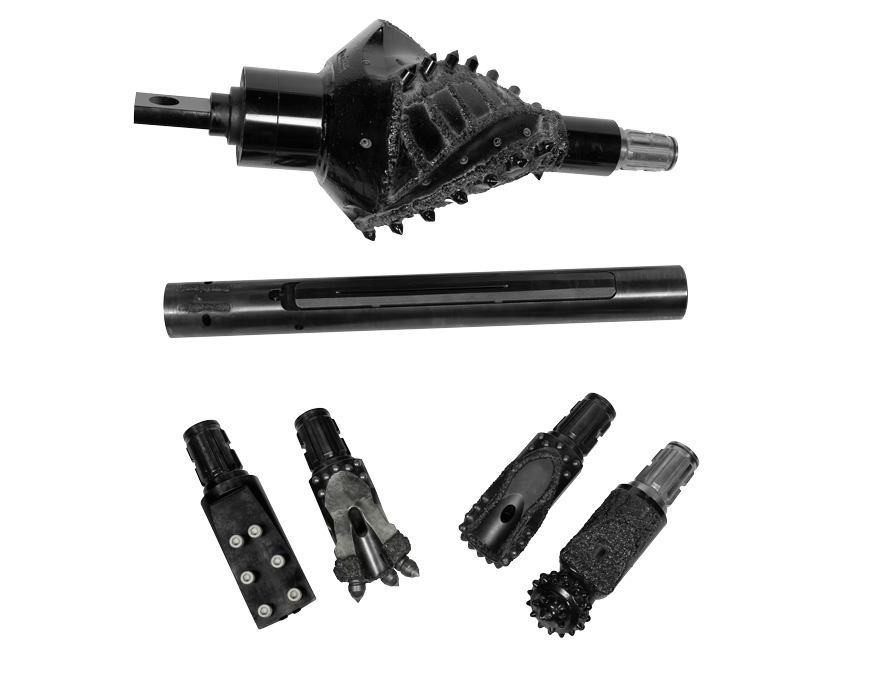

The Ultra X3 drill head system from Vermeer is designed to help you switch drill tooling quicker on the jobsite. It’s the only integrated drilling system on the market that enables HDD operators to quickly swap drill bits. The Ultra X3 lineup is crafted from durable, high alloy material which is especially beneficial if you frequently work in challenging, abrasive ground conditions. This drill bit family is rated for soft rock, cobble, dirt, clay and loam.

Let’s look at what makes the Ultra X3 system a unique drilling solution and compatible HDD tooling options.

What are the key features of the Ultra X3 drilling system?

The Ultra X3 lineup offers a non-torqued option for bit changeouts and is available in three sizes — equipped for drill rigs up to 40,000 lb (18,143.6 kg), making it a versatile and valuable tool for jobs of all sizes.

No breakout tongs necessary

The Vermeer Ultra X3’s robust spline connection system eliminates the need for threading and breakout tongs. Operators simply align the splines on the tooling and housing, then secure the tooling by tapping in dowel pins.

Ream from the transmitter housing

The system can handle reaming diameters up to 12 in (30.5 cm) from the transmitter housing in most conditions. It supports a full range of HDD plate bits and rock tooling as well as two reaming options, fluted and mixing, and pull eye or swivel options.

The Vermeer Ultra X3 features interchangeable pilot and pullback tooling without the need for torqued or threaded components, and it can ream directly off the transmitter housing. For certain applications, it can eliminate the need for starter rods and adapters. The Ultra X3’s strong spline connection can handle the torque of reaming directly off the transmitter housing in most conditions.

This system enhances jobsite efficiency by reducing the size of your exit pit, and time needed to dig an exit pit. Its design allows HDD crews to switch from pilot to pullback in a smaller space without removing the housing for most pullbacks, minimizing repetitive lifting. This also means smaller pits, which can lead to less jobsite restoration work.

Advantages of Quick-Connect

The Ultra X3 housing features a standard API rear connection and is compatible with quick-connect systems like the Vermeer QuickFire® connection system. Contractors can save on starter rods and collars thanks to the quick-connect on the bit side of the housing, with the Ultra X3 system also being lead rod compatible.

Available sizes for the Ultra X3 system

The three different options for the Ultra X3 system are nearly identical, aside from the differing sizes and drill compatibility. It’s important to note that the Ultra X3 system can be used on both Vermeer and Ditch Witch® drills — which is ideal if you have a mixed fleet of equipment.

Ultra X3 275

The Ultra X3 275 is the smallest option in the Ultra X3 tooling lineup at 2.75 in of the outer diameter. It’s equipped with reaming capabilities of 6 in and 8 in (15.2 cm and 20.3 cm). It’s designed for horizontal directional drills in the 10,000-lb (44.5-kN) drill range — which includes the Vermeer D10x15 S3 or Ditch Witch JT10 HDD.

Ultra X3 325

Ultra X3 325 is designed for HDDs in the 24,000-lb (106.8-kN) drill range — Vermeer D23x30 S3, Vermeer D24x40 S3 or Ditch Witch JT30 HDD. It comes in three reaming capability options at 6 in, 8 in and 10 in (15.2 cm, 20.3 cm and 25.4 cm).

Ultra X3 375

The most robust in the Ultra X3 lineup is the Ultra X3 375 with 8 in, 10 in and 12 in (20.3 cm, 25.4 cm and 30.5 cm) reaming capability options, as well as measuring at 3.75 in (9.5 cm) of the outside diameter. Built for HDDs in the 40,000-lb (177.9-kN) drill range — like the Vermeer D40x55 S3 or Ditch Witch JT40 HDD.

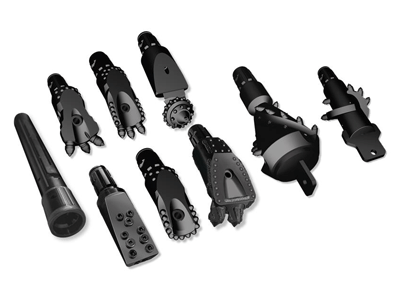

What drill bits are compatible for the Ultra X3 system?

There is a wide selection of tooling options that are compatible with the Ultra X3 system. The versatility of tooling can enable you to rely on the Ultra X3 system no matter what jobsite conditions you encounter.

Dirt bit sub

The dirt bit sub is equipped for many ground conditions. Operators can bolt-on any Vermeer plate bit offerings to match the ground conditions ahead. Bit Boss™ retention system shoulder screws on Ace™ and Gladiator bits help decrease the force that could shear off bolts downhole. This enables improved reliability throughout your drill string and reduces tooling replacement.

Lance Pro bit

The Lance Pro bit offers continuous carbide coverage across the front of the bit to help extend wear life while featuring domed, plug-style teeth. This bit can be rebuilt and is better protected from wear thanks to carbide buttons to protect the bit mount section. With a tendency to cut on center, the Lance Pro bit helps you execute precise bores as planned. This bit is intended use in hard packed soils, highly abrasive cobble and cemented cobble.

Lance Trident bit

Designed for soft rock, shale and caliche is the Lance Trident bit. For improved wear resistance, carbide buttons are brazed on the sides as well as replaceable conical teeth. Lance Trident bits also have the option to rebuild once worn down. To learn more about the drill bit rebuild process, your local Vermeer dealership can assist you.

Single Roller Cone bit

The Single Roller Cone bit is built for cobble and dense cemented cobble. It features a single carbide tipped roller cone extracted from a tricone rock bit. The roller cone is welded onto the bit mount, creating space to cut and move cobble with ease. For even better steering performance, a steering shoe with carbide grit is welded onto the steering shoe.

Gauntlet bit

The Gauntlet bit is best suited for working in soft, solid rock and broken formations. It features three replaceable carbide-tipped conical teeth that are replaceable as they wear down, with grit carbide being applied to high-wear areas. Carbide buttons are placed onto the steering shoe to aid in bit wear and steering performance. This is another rebuildable bit offered by Vermeer to help minimize costs on HDD tooling.

2Thirty™ bit

The newest addition to the Ultra X3 lineup is the 2Thirty bit. It’s designed to tackle tough ground conditions like broken, hard rock. It features two oversized conical teeth set at a 30-degree angle to aggressively attack rock formations. This bit also features carbide buttons and carbide grit in high-wear areas. It’s the last line of defense before utilizing an air hammer or dual rod rock drill and is limited in steering performance.

If you want to swap drill bits faster than you thought possible, consider adding the Ultra X3 system to your toolkit. It’s designed for operators who frequently tackle changing ground conditions and want to get work done efficiently. For more information on the Ultra X3 drilling system, get in touch with a BORESTORE® HDD tooling specialist at your local Vermeer dealership.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation.

Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo, Equipped to Do More, QuickFire, Bit Boss, Ace, 2Thirty and Borestore are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. Ditch Witch is a trademark of The Charles Machine Works, Inc.

© 2025 Vermeer Corporation. All Rights Reserved.