For quarry operators looking to improve efficiency and gain better control over operating costs compared to traditional drill and blast methods, continuous surface mining technology presents a compelling alternative. Italian construction and quarrying company Ecoin S.p.A. faced this exact challenge at its Cava Primosole limestone quarry. By integrating Vermeer T1055III and T1255III surface miners into their operation, they not only boosted production significantly but also gained economic advantages in their extraction process.

Moving beyond traditional extraction methods

Based in Catania, Sicily, Ecoin operates the Cava Primosole limestone quarry to support its construction activities and growing concrete business. This quarry provides essential raw limestone utilized for surveys, road ballasts, fillings and subsoils, processed through crushing and screening processes, with the resulting material undergoing chemical analysis and laboratory tests to define its characteristics and verify quality control. Ecoin maintains a large fleet, including hundreds of trucks, wheel loaders, excavators and bulldozers to support its extensive operations.

Prior to adopting surface miners, Ecoin primarily used explosives for mining limestone, representing about 80% of their extraction method, sometimes combined with ripping using large dozers. While functional, these traditional approaches presented limitations in cost control and achieving consistent material quality, prompting Ecoin to explore alternative extraction technologies.

Discovering the Vermeer advantage

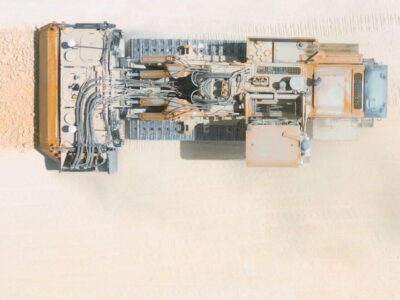

Ecoin’s solution was to combine their existing methods with Vermeer continuous surface mining technology by investing in T1055III and T1255III surface miners. Owner Gaetano Caruso initially had reservations about the new technology but changed his mind after witnessing the machines’ capabilities firsthand. “Testing the machine opened my eyes to its capabilities,” he stated. The journey began three years ago when they tested a smaller Vermeer surface miner. The impressive results and quality of the finished product from this trial led directly to purchasing the larger T1055III. “And we started working a lot with it,” Mr. Caruso added.

Later, after witnessing the powerful T1255III in action during a demonstration Vermeer held at their site, Ecoin decided to add that model to their fleet as well. Now, Ecoin operates both machines, utilizing each strategically based on the desired output.

“We use the machines for different types of material,” Mr. Caruso explained. “The T1255III produces coarser material, 200–250 mm (7.9–9.8 in), while the T1055III creates a finer, finished product. Being able to customize the output directly from each machine is a significant advantage.”

Ecoin currently uses a hybrid approach in their quarry operations. In the upper sections, where limestone composition is not uniform, they continue to use traditional explosive methods. For the lower sections containing pure, homogeneous bench limestone, they rely exclusively on the Vermeer T1055III and T1255III surface miners. While surface miners now handle about 50% of material extraction, Ecoin plans to eventually transition all quarry operations to these machines.

Achieving production gains and economic efficiencies

Two key factors drove the decision to switch to Vermeer surface miners: the superior quality of finished product produced directly by the machine and the significant cost savings in the extraction process. Mr. Caruso attributes substantial savings to the larger machine, stating, “I decided to add the T1255 because there is a reduction of material excavation and production costs by 70% to 80%.” He also noted, “Both machines are truly excellent and their performance is outstanding,” adding that the overall equipment quality exceeded expectations.

Production capacity also saw a remarkable increase, addressing production needs at Ecoin. With the T1255III operating under normal site conditions, Ecoin can produce up to 6,000 m³ (7,848 yd3) of quality product per day. Mr. Caruso contrasted this with the T1055, estimating its output at 2,000 m³ (2,616 yd3) per day, highlighting the T1255’s ability to triple production under similar conditions. This substantial output allows Ecoin to efficiently meet the demands of its large-scale construction projects and third-party supply commitments.

Beyond production operational benefits and support

The Vermeer surface miners offer benefits well beyond production volume and cost management. The machines quickly produce large quantities of precisely sized material. The T1055III combines a Caterpillar C13 ACERT Tier 4 Final engine with a top-down cutting system for enhanced rock penetration. The T1255III can cut steep 80-degree high walls, enabling mines to access reserves that would be off-limits due to drill and blast restrictions, air quality regulations or urban development. Compared to traditional methods, these machines also generate less noise, dust and vibration.

Operational efficiency is enhanced by features like the integrated GPS system, which delivers precise and efficient project alignment. Furthermore, the machines run quietly and boast low fuel consumption.

Ecoin also highlighted the excellent relationship they have with Vermeer Italia. Technical support has been consistently responsive and well-equipped, described as being “just a phone call away when needed.” Response times for onsite support have been described as “incredibly quick,” fostering an excellent rapport over their three-year business relationship.

Doing more with Vermeer surface miners

Ecoin’s experience demonstrates the clear advantages Vermeer surface miners bring to quarrying operations. Integrating the T1055III and T1255III has helped the company achieve substantial production gains, reduced excavation costs and improved material quality while enhancing operational efficiency through advanced features and systematic quarry management. This technological shift has enabled better quality control and maximized the value of extracted materials. With strong support from Vermeer Italia, Ecoin’s strategic adoption of surface miners has proven successful, strengthening their market position.

As owner Gaetano Caruso simply put it: “My name is Gaetano Caruso, and I chose to do more with the T1255.”

Get started today

Transform your mining operation with Vermeer surface miners. Connect with your local Vermeer dealer to explore solutions tailored to your site’s needs.

This article contains third-party observations, advice or experiences that do not necessarily reflect the opinions of Vermeer Corporation, its affiliates or its dealers. Testimonials and/or endorsements by customers in specific circumstances may not be representative of normal circumstances experienced by all customers.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation.

Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications.

Caterpillar is a trademark of Caterpillar, Inc. Vermeer, the Vermeer logo and Equipped to Do More are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2025 Vermeer Corporation. All Rights Reserved.