To install the right kind of piles, you need the right kind of guide. What kind of guide you need depends on the piles you’re installing. So, it’s important to choose a guide that will fit the job.

Think of a pile driver guide as the boundary lines that surround the pile and keep it on its intended path. It’s there to make sure your piles get driven into the correct place in the correct way. The guide you choose depends on your hammer opening, orientation, loading position, and the pile shape and dimensions. Let’s go through each of those and see why they’re necessary to consider when selecting the right guide.

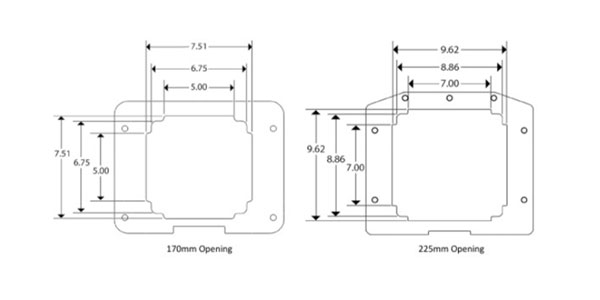

Hammer opening

There are two kinds of hammer openings you may have: either a standard opening hammer (170 mm/6.7 in, which is no longer being produced) or a large opening hammer (225 mm/8.9 in). Vermeer pile drivers mostly use large opening hammers, but it’s worth it to double-check which kind you have, as there are some older machines with standard opening hammers still in the field.

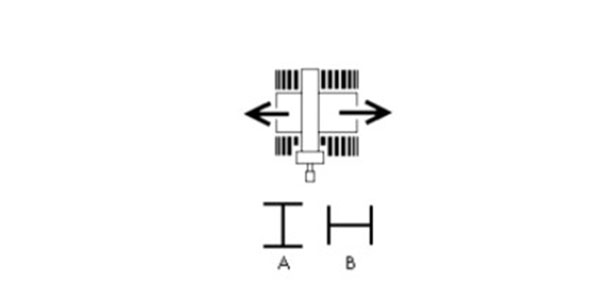

Orientation

The next thing to consider is what orientation your post is going to be. There are different guides for each one.

“To determine the orientation, look at an I-beam from the end,” explained Bo Howell, Vermeer product specialist. “Is the center portion of the I-beam perpendicular or parallel to the tracks of the pile driver? If the I-beam is perpendicular, it’s considered Orientation A. If the I-beam is parallel, it’s considered Orientation B. The most common one is Orientation A, because of the nature and setup of most solar sites, but it’s not unusual to see Orientation B at certain times.”

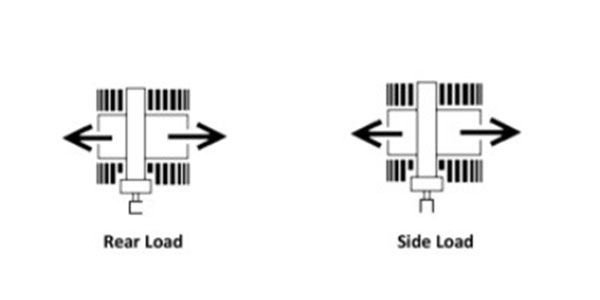

Loading position

After that, consider the loading position of the pile driver. Are you going to be loading the piles from the rear or the side? There are times that both can be beneficial, but there is a specific guide for each loading position. With the rear load, the guide is open to the rear of the machine, and with side load the guide is open to the side of the machine.

“With a rear load guide, you can drive the machine away from the post after it’s driven, versus having to retract the mast with the side load guide,” said Howell.

The rear loading guide goes from W6x7 up to W6x25, and the side loading guide goes from W8x10 to W8x28.

“The dimensions on the guides, like W6x7 for example, doesn’t mean that it’s six by seven inches,” said Howell. “W means wide flange, six means it’s six inches in a direction, and seven means it’s seven pounds by linear foot. That’s how structural steel is sized.”

It’s also helpful to note that these are available for large opening hammers only.

Pile shape and dimensions

The pile shape and dimensions of the pile should also be taken into account.

First, consider the shape. Is it an I-beam, is it round, is it a c channel? Then, figure out the dimensions. If it’s something common, like a W6x9 I-beam, that’s all you need to include. Knowing this determines if you can use multi-fit, the upper pile driver guide.

“The nice part is pile driver guides, like multi-fit, can accommodate a wide range of post sizes, so you don’t have to swap guides every time you switch post sizes,” said Howell. “However, these are bolt-on guides, and can take a little more time to swap out in the field.”

As you select your pile driver guides, consider these four areas to help guide your decision. These guides are available to order now from your local Vermeer dealer. If you have any questions, reach out to them today.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo and Equipped to Do More are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries. © 2021 Vermeer Corporation. All Rights Reserved.