Got trouble drilling in cemented cobble? Perhaps you are struggling to steer in soft ground conditions?

We understand — drilling is challenging work.

But there’s good news. Vermeer has the right horizontal directional drill bit for those headaches — and many other problematic ground conditions that give drillers fits.

Vermeer offers more than 20 HDD bits on borestore.com, where you can find product details, breakdowns of best HDD bits for specific ground conditions, prices and much more. Cody Mecham, the Vermeer product manager for Cutting Edge, outlined common ground condition problems for drillers. Here are his suggestions for the best HDD bit for each situation.

HDD drill bit problem: Penetrating cobble

Cobble presents numerous problems for directional drilling: It’s extremely hard and difficult to steer through. As drillers know, it’s one of the most challenging ground conditions you’ll come across.

Best HDD bit for cobble

Moderate cobble: The Ace™ Pro Bit

The Ace™ Pro Bit was engineered to tackle a variety of ground conditions drillers encounter: cobble, loam, sand and hard pan.

If you are drilling in moderately aggressive cobble, Mecham suggests this as the best HDD drill bit.

“Featuring a semi-aggressive taper for penetration into tough ground conditions, paired with brazed-in-place carbides for wearability, this bit thrives in moderate cobble,” he said.

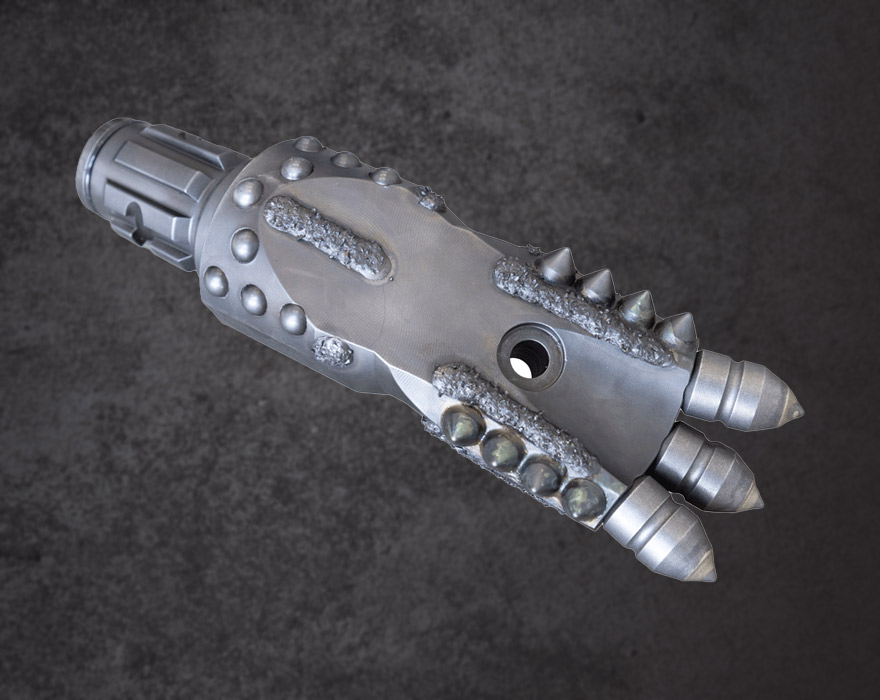

Tough cobble: Ace Pro Extreme Bit or Ultra X3 Lance Pro

For those who need a solution for dense cobble, the Ace Pro Extreme Bit may be the answer. The dome-style carbide teeth on the Ace Pro Extreme were built for rugged ground conditions and positioned closer together for better wearability.

“This bit features an aggressive front taper for penetration, as well as extended plug carbide coverage for extended wearability,” Mecham said.

The other top option for difficult cobble is the Lance Pro, which utilizes the Vermeer Ultra X3 drilling system. This drill bit offers extended wearability thanks to its dome-style carbide and allows drillers to bore on center to execute bore plans.

“The Lance Pro is also rebuildable, offering the ability to get a new cutting structure welded on — also extending the wearability of the bit,” Mecham said.

How HDD maintenance maximizes productivity

HDD drill bit problem: Steering in soft ground conditions

It’s not just ancient rock that can give drillers problems. Ground conditions, such as dirt and loam, can even create issues if the conditions are too soft. Steering becomes a time-consuming issue if the ground conditions become too soft.

Best HDD bit for soft ground

Ace Standard Bit

The Ace Standard Bit has a rounded bit face that provides optimal steering in softer ground conditions. It was engineered for boring through various soil types and loam. Another option would be the Ace Pro Bit.

“The Ace Standard Bit features a flat bit front, allowing for aggressive steering ability,” Mecham said. “Something like the Ace Pro Bit is also going to steer well in this ground condition and allow you to get through some tougher ground conditions as they arise due to additional carbide buttons.”

Another options Mecham suggests is the Gladiator family of drill bits from Vermeer.

HDD drill bit problem: Steering in soft rock

Vermeer has engineered several quality drill bits focused on rocky ground conditions, such as sandstone, shale, limestone, caliche and coral. Those ground conditions are difficult for steering.

Best HDD bits for soft rock

Ultra X3 Lance Trident

Built for soft rock and hard soil, the Lance Trident, with the Ultra X3 drilling system, has three replaceable teeth that can handle up to 3,000 psi (20.7 MPa).

“The Trident gets great penetration while having a flat steering face like the Lance Pro to get rapid steer in tough ground conditions,” Mecham said.

Ultra X3 Gauntlet

If you need something that can handle more psi drilling in soft rock, the Ultra X3 Gauntlet may be your answer. It is built to handle up to 8,000 psi (55.2 MPa).

“However, it doesn’t possess as much steerability as the Trident,” Mecham said.

HDD drill bit problem: Drilling in cemented cobble

Cemented cobble is used to describe cobble that has been compacted over many thousands of years. As it does, it packs tightly. It’s among the toughest ground conditions that drillers face.

Ultra X3 Single Roller Cone

Engineered for cobble and broken formations, the Single Roller Cone is a top option to solve this HDD issue.

“The cone rotation helps smooth out the drill string, helping reduce torque spikes,” Mecham said.

Ace Premium Bit

For those using a plate bit, the Ace Premium Bit would be Mecham’s choice.

“Penetration from the taper paired with the durability and wearability due to the carbide placement makes this bit ideal for aggressive ground conditions such as cemented cobble,” he said.

If you have any additional questions about HDD bits, contact your local Vermeer dealer.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region.

Please contact your local Vermeer dealer for more information on machine specifications. Vermeer, the Vermeer logo, Borestore and Ace are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2024 Vermeer Corporation. All Rights Reserved.