At Vermeer, designing innovative equipment to find a better way to do important work is nothing new. Decades since the first horizontal directional drill was brought to market, Vermeer is still improving and redesigning equipment to meet the needs of today’s operators.

So, when horizontal directional drilling (HDD) was a brand-new — but unproven — concept of installing utilities, Vermeer was interested to see how this process worked. It was obvious that horizontal directional drilling could make installation easier for operators and provide less disruption to residential areas than open-cut trenching.

One Vermeer employee who has been on the HDD journey for an impressive 47 years is Jim Rankin. Rankin was instrumental in the development of the first Vermeer horizontal directional drill and has been supporting HDD equipment in the field ever since. He has decades of industry knowledge and experience that demonstrates how impressive today’s equipment is, and how influential Vermeer technology and innovations have been for the HDD industry.

So, who is Jim Rankin?

Jim Rankin was raised on a livestock and row crop farm in Reasnor, Iowa — about 20 minutes northwest of Vermeer headquarters in Pella. At just 19 years old, Rankin started his career at Vermeer as a welder in 1977. Since that first role at Vermeer in 1977, Rankin has worked as a welder, assembler, engineer and now a field service manager.

Rankin first got involved with horizontal directional drills in the late 80s, when Vermeer began exploring the possibility of a pneumatic piercing tool. When he first entered the engineering department in 1982, Rankin was on a team tasked with exploring unknown technology at the time, which included horizontal directional drilling. Only two years later, Vermeer launched five drills into the field for testing. After two years of testing, the first self-contained Vermeer HDD, the D7, went to market in 1993.

The D7 Navigator® HDD was the first drill built by Vermeer and was a simple design much like other machines offered by competitors. The D7 required more manual operation and labor to set up compared to drills offered today. But at the time, the D7 was a popular and competitive drill in the market.

For Rankin, one of the most memorable products to launch throughout his career was the D24x40 self-contained drill in the late 90s. This model was a hit in the HDD market as it reduced labor on the jobsite needed to set up, carry and load rod. It also had robust power to make and break drill rod with ease.

“It was pretty exciting to see this new drill we worked hard on be as successful as it was. It felt like everyone wanted a D24x40, and we were happy that many customers found so much success running it,” Rankin explained.

Rankin has seen firsthand how the jobsites have changed throughout the years and has witnessed the impact machine improvements and technology can have on a utility jobsite. Instead of helping design the equipment — like the D7 — Rankin now visits customers and operators in the field as needed to help maximize their productivity and efficiency.

Changes in HDD jobsites through the years

When Vermeer entered the HDD market in the 80s, jobsite and equipment needs were vastly different compared to what is being used today.

Rankin explained, “In earlier drill models, performing a basic bore was more labor intensive. Everything used to be much slower, larger and just more cumbersome. Especially with more automation on the machine, elements of drilling are just less labor intensive then it used to be.”

A major hurdle for Vermeer — and other manufacturers at that time — was that horizontal directional drilling as a concept was unproven and unknown to the utility industry. Today putting utilities underground with a drill is more widely accepted, partly due to the changing jobsites with more residential areas, along with labor-saving and technology improvements in equipment.

“Comparing jobsites from the early 90s to now, things have changed a lot. An obvious difference is that the right of ways are a lot more crowded than they used to be. But thanks to HDD, those right of ways are more durable and sturdier since we can go right underneath rather than open trenching to lay utilities.”

Locating technology has also improved over the past 40 years. When contractors are facing congested jobsites, unmarked utilities and stricter regulations, making timely and accurate locating is essential for utility installation.

“Back then, not as many utilities were buried. Now, with the increasing number of utilities underground locators and vacs are even more essential than ever,” Rankin said.

Rankin’s experience, knowledge and accomplishments in the HDD industry are difficult to articulate. He has supported equipment and customers with nearly every drill Vermeer has launched and has seen firsthand the countless ways the HDD industry has evolved.

From narrowing jobsites, labor shortages, new automation and technology — Rankin has been there for it all.

The Next Generation of Vermeer drills

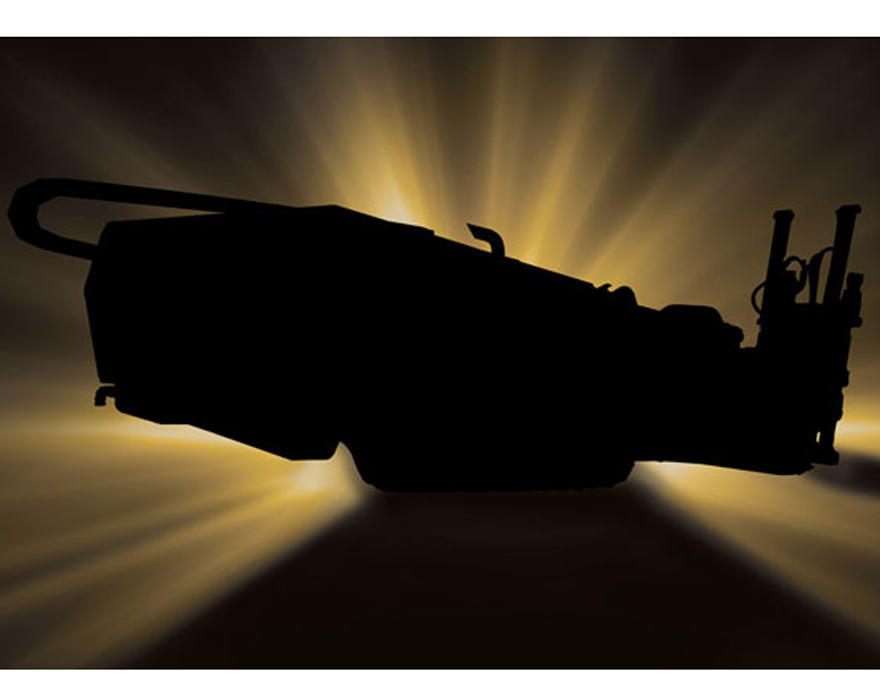

Vermeer is embarking on a new era in horizontal directional drilling.

Since launching into the HDD market in the 1990s, the number of utilities going underground has increased dramatically — which means jobsite, industry and operator challenges have increased as well. With more and more utilities going underground every day, a highly productive and reliable machine is needed to get more work done per day. The Next Generation of utility drills have been redesigned to face the challenges of an evolving industry. This new drill will help streamline utility installation, maximize component durability and provide unprecedented machine insights.

To learn more about the innovations and enhancements featured on Next Generation drills, get in touch with your local Vermeer dealer.

Vermeer Corporation reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer, the Vermeer logo, Equipped to Do More and Navigator are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2024 Vermeer Corporation. All Rights Reserved.