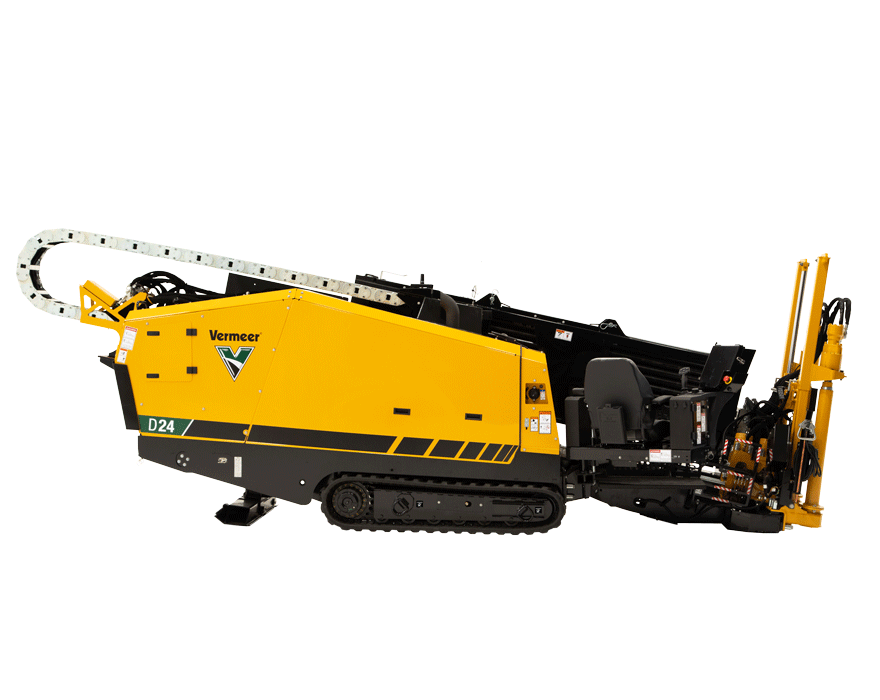

If there’s one thing we pride ourselves on at Vermeer, it’s listening. When utility contractors talk about their challenges in the field, we don’t just hear them — we build solutions around them. That’s exactly what we did with the D24 horizontal directional drill (HDD), the latest addition to our utility drill lineup.

Since the D24 HDDs launch in November 2024, we’ve seen a flurry of questions across social media platforms. Our Instagram comments section, LinkedIn posts and YouTube comments have been buzzing too!

You’re curious, and rightfully so. This machine represents a significant step forward in HDD technology, designed specifically to address the pain points we’ve heard from utility contractors: labor constraints, reliability concerns and the need for enhanced productivity.

So let’s dig into the 15 most common questions we’ve gathered about the Vermeer D24 HDD.

1. What Vermeer model is the D24 HDD replacing in the current lineup?

The D24 HDD is replacing the iconic Vermeer D23x30 S3 HDD. Building on the robust foundation of its predecessor, the D24 introduces automation and smart diagnostics that enhance operator capabilities and help boost jobsite productivity.

2. Why is it called the D24 HDD?

We’re simplifying our nomenclature. The “D” stands for drill, and “24” represents the 24,000-lb (11,000 kg) thrust/pullback class. This simplified naming convention makes it easier to identify the machine’s capabilities at a glance.

3. What engine and horsepower does the D24 HDD have?

The D24 HDD features a 100 hp (74.6 kW) CAT® C3.6 engine that runs on ultra-low sulfur diesel with a maximum engine rpm of 2,000, providing plenty of power for demanding drilling operations while maintaining fuel efficiency.

4. What are the push/pull specifications?

The D24 HDD delivers 24,700 lb (110 kN) of maximum peak thrust/pullback. The continuous thrust/pullback is 22,000 lb (98 kN), providing reliable performance throughout operation.

5. How many feet of rod does it hold?

The D24 HDD offers two rod capacity options: 400 ft or 480 ft (122 m or 146 m) of 2.375 in (6.03 cm) Firestick® drill rod. This increased capacity compared to previous models means you can work longer without changing boxes or manually adding more rod.

6. What size rods does it use?

The D24 HDD uses 2.375 in (6.03 cm) diameter drill rod with #600 threads. The rod length is 10 ft (3 m).

7. How does the carriage speed compare to previous models?

The D24’s carriage speed has been optimized for productivity. The thrust motors have been changed from three lower displacement thrust motors to two larger displacement radial piston motors with integrated thrust encoders. This allows for lower internal pressure while maintaining high performance. The encoder has been tested and fine-tuned on slow down and stop points to maximize speed while helping components, resulting in more efficient operations and extended component life.

8. What is the ARE system and how does it reduce machine damage?

The automated rod exchange (ARE) system is one of the D24’s standout features. With a single button push, the system completes the entire rod changeout sequence automatically — reversing rotation to disconnect joints, applying grease, presenting new rods and making up new connections. This automation delivers consistent performance that helps protect components by properly managing makeup pressures and thread engagement, potentially extending the life of sub savers, vise dies, magnets and rods.

9. How reliable is the automated rod loading system?

The ARE system has undergone extensive cycle testing to deliver reliable performance. It completes a drill-out operation in approximately 26 – 27 seconds and a pullback operation in the mid-30s second range. The system is designed with multiple self-checks — if certain criteria aren’t met, it will stop and notify the operator of the issue. This level of protection helps maintain consistent, reliable performance throughout the workday.

10. Does automation slow down experienced operators compared to manual operation?

While some experienced operators might be slightly faster manually, the ARE system delivers consistent performance throughout the day regardless of operator fatigue. The system also performs multiple operations simultaneously for maximum efficiency. The real advantage comes in improved component life and consistent, reliable operation hour after hour, day after day.

11. Why put a touchscreen on an open cab drill?

The touchscreen provides access to advanced diagnostics and machine settings that simply weren’t possible with traditional controls. It gives operators unprecedented access to machine data that can help them make key service decisions right from the seat. And don’t worry — the D24 HDD still maintains physical controls and joysticks for core drilling functions.

12. How does the touchscreen function with gloves or dirty hands?

The touchscreen is designed for jobsite conditions and works with gloves. For situations where the touchscreen may not be preferred, the D24 HDD still includes a push-button vehicle display control dial as an alternative interface option. The interface provides access to drill settings, screen setup and diagnostic screens with information equivalent to what a service technician would have for diagnostics and troubleshooting.

13. Is there a D24DR (dual rod) HDD version available or planned?

While we can’t comment on specific future product plans, the current D24 HDD is designed as a single rod machine. The D24 HDD builds on the legacy of the D23x30 S3 HDD with next generation technology and features. For contractors requiring dual rod capability, Vermeer continues to offer other models in our lineup with this functionality. As always, we’re constantly evaluating market needs and customer feedback to guide our product development.

14. What warranty does it come with?

The D24 HDD comes with an industry-leading 3-year, 3,000-hour OEM extended warranty program. This comprehensive coverage reflects confidence in the enhanced hydraulics, electrical design and power train system that have been designed for maximum reliability. This warranty program sets a new standard in the industry and demonstrates our commitment to the D24’s long-term performance.

15. What is the price of the Vermeer D24 HDD?

We knew this question was coming! The D24 HDD is available in two primary configurations: with a 400 ft (122 m) rod box capacity or a 480 ft (146 m) rod box capacity. While exact pricing may vary based on your location, your local Vermeer dealer can provide you with detailed information on both configurations and available options. They can also discuss financing options to help you get the right D24 HDD for your operation.

The next generation is here

The D24 represents more than just a new machine — it’s the future of directional drilling at Vermeer. With its advanced automated features, enhanced diagnostics and reliability and labor-saving technology, the D24 is designed to help you tackle the challenges of modern utility installation efficiently and productively.

We appreciate all the great questions from our social media followers on Facebook, Instagram, LinkedIn and YouTube. Your feedback and curiosity continue to drive us forward as we develop solutions for the challenges you face every day. If you have more questions about the D24, feel free to post them on our Vermeer social media channels — we’re always listening and ready to respond.

Ready to experience the D24?

Want to see the D24 HDD in action or learn more about how it can help boost your productivity? Contact your local Vermeer dealer today. They’ll be happy to show you how the next generation of Vermeer HDDs is redefining what’s possible on the jobsite.

Vermeer Corporation reserves the right to make changes in product engineering, design and specifications; add improvements; or discontinue manufacturing or distribution at any time without notice or obligation. Equipment shown is for illustrative purposes only and may display optional accessories or components specific to their global region. Please contact your local Vermeer dealer for more information on machine specifications.

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the U.S. and/or other countries.

© 2025 Vermeer Corporation. All Rights Reserved.