How to boost horizontal directional drill jobsite efficiency with the Ultra X3 drilling system

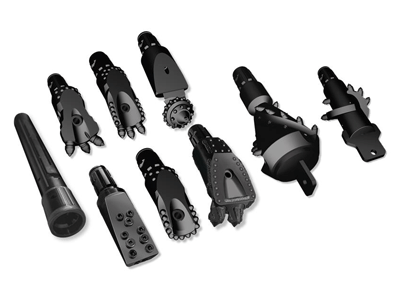

If you have been searching for a tooling solution to help boost your HDD jobsite productivity, look no further. See how the Ultra X3 tooling system and compatible tooling options can support your crew.

Read More